Navigating Troubled Waters: The Contingency Mentality

Logistics contingency plans are just a fancy way of conveying the importance of businesses being prepared when the ship hits the fan—like if the Ever Given lodges itself at the Suez Canal or a viral pandemic hits planet Earth like a meteor, somehow super-charging global consumerism.

In 2021, an estimated 40% of all global ocean bookings were delayed or rolled from March to May, which caused carriers to deploy wave after wave of blank sailings to help get vessels back into their proper rotations. Covid was one gigantic contingency plan: global shippers placed their contracted cargo with their intended carriers just 50% of the time, and they paid the rates they expected for just 10% of all bookings! 2023 saw a return to stability and rational planning, but here comes 2024…!

Currently, we see two main assaults to your well-crafted supply chain plans, scholarly shippers: Panama and Suez Canal-sequences and ILA Labor Pains.

Panama & Suez Canal-sequences

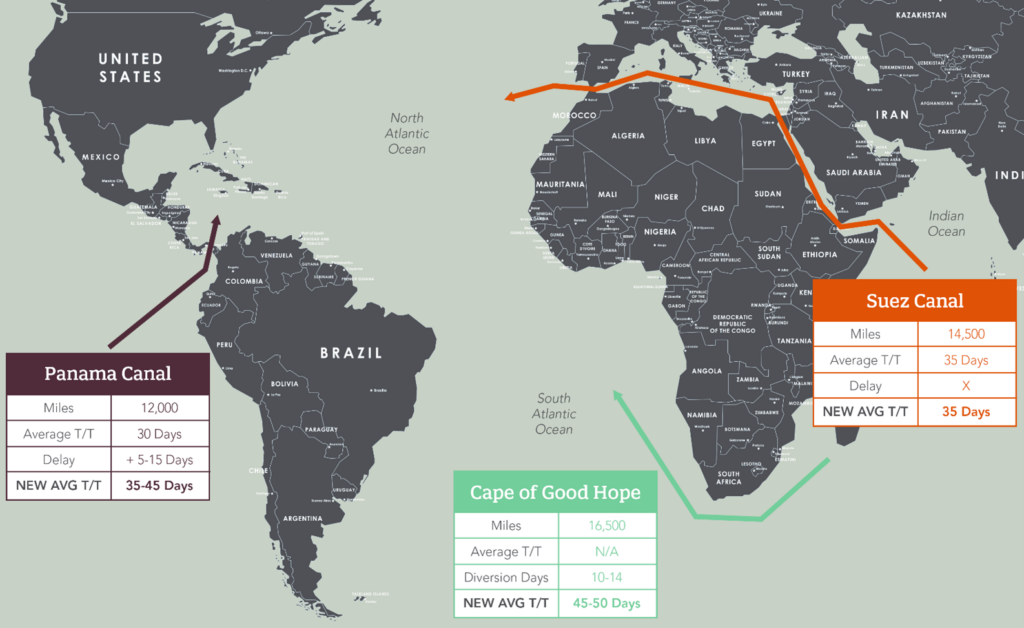

Please have a look at the global ocean routing map and supporting data points below, comparing expected transits from Base Ports in Asia to Base Ports on the US East Coast (USEC):

- Approximately 30% of global cargo volume transits the Suez.

- In normal times, about 35% of USEC volumes utilize the Suez.

- Ocean rates have doubled in a month, despite only modest seasonal demand growth.

- Not to mention the Emergency Risk (Suez) and Emergency Drought (Panama) Surcharges…oh my…!

- 17 of the 23 main service routes from Asia to US utilize Panama.

- Of the 17 services, 4 have returned to Panama after attempting Suez routing.

- 24 ships may transit Panama’s locks each day—which is just 67% of normal capacity.

So, what are we all going to do if Iran continues to fund the Houthis in the Red Sea and Mother Nature continues to deprive Panama of her ship carrying rains?

ILA Contractions & Labor Pains

Early news reports of International Longshoremen’s Association (ILA) contract renewal demands for the US Gulf and East Coast indicate very high wage and benefit expectations and zero automation tolerance. What can we do in the case of a major strike?

After prayer, meditation, and yoga, we have to begin with these fundamental questions:

- What happens to my production lines and inventory levels if my shipments are delayed?

- What additional fees might be imposed on my shipments by the lines?

- What if I can’t secure cargo space?

- What are the pros and cons of alternative cargo routings?

- Does my insurance cover delayed or rerouted shipments?

- What can I expect for ocean freight levels after Chinese New Year?

- Am I prepared to move some of my cargo by airfreight?

- Do I have the right partners in my supply chain who can give me access to both canals and all ocean carrier alliances?

- Have I investigated alternate product sourcing options with avoiding canals in mind?

- Should the ILA strike, what USWC options have I established in advance?

- Have I budgeted for contingencies? For example, if I ship zero containers over the West Coast through August, how will I expect to get space there after a strike?

The current global political and climate realities make it clear that proactive planning is crucial. But how does one go about creating an effective contingency plan?

Things to Consider When Creating Your Contingency Plan

Let’s dive into the practical steps and considerations that should be evaluated for your unique situation:

- Risk Assessment of Supply Routes: Assess risk by identifying potential vulnerabilities in your supply chain. Consider factors like geographical positioning and risks, political stability of trade routes, and dependency on key channels like the Suez or Panama Canal.

- Inventory Management: Determine the optimal level of safety stock for key products to buffer against supply chain disruptions. Diversify your supplier base to avoid disruptions in the event of trade tensions as recently seen with the US and China. Forecast demand of product to adjust inventory levels ahead of important seasons.

- Scenario Planning: Develop scenarios for various types of disruptions, ranging from natural disasters to geopolitical tensions. Consider the likely impacts on your routes, timelines, and costs.

- Alternative Routes and Modes: Map out alternative shipping routes and modes of transport. Evaluate the feasibility, cost implications, and transit times of each alternative. A mix of options is crucial as plan B can often become unavailable as we are seeing today with the Suez Canal.

- Contract Flexibility and Insurance/Liability: Negotiate contracts/deals with carriers/NVOs that allow for route flexibility and ensure that you have a comprehensive understanding of insurance coverage and the liabilities you have connected to the delivery of product.

- Leverage Technology: Technology, like Shapiro 360°, plays a pivotal role in being able to track shipments in real-time to reroute cargo and manage schedules as soon as possible. These indispensable tools help mitigate the risk of disruptions.

Contingency Consequences & Conclusions

Developing a comprehensive plan is important but it’s equally important to ensure your plan remains relevant and effective. Normally, reviewing your plan on a semi-annual or annual basis does the trick. For 2024, we recommend monthly reviews—especially considering the on-going canal concerns. This will give you the opportunity to update your tactics and strategies in concert with the latest market trends, technological advancements, and changes in trade policies (to say nothing of global geopolitics and Mother Nature…!).

We understand that the complexities of contingency planning can be overwhelming. If you feel daunted by the prospect of developing or updating your contingency plan, you don’t have to go it alone. Shapiro’s team of experts is here to guide you through every step of the process. Contact us for personalized support and guidance to be prepared for any challenge that may arise.

Helpful Links/Related Topics: