Cross-Docking in Logistics: Definition and Benefits

What Is Cross-Docking? A Logistics Strategy That Saves Time and Money

Cross-docking is a warehouse and logistics strategy where inbound shipments are unloaded and directly reloaded onto outbound trucks—with little or no storage time in between. In type of operation, goods move quickly through a facility, reducing inventory holding costs and speeding up delivery times.

For importers, retailers, and e-commerce brands, cross-docking services offer a faster, leaner alternative to traditional warehousing, especially when speed to market is a competitive advantage.

How Does Cross-Docking Work?

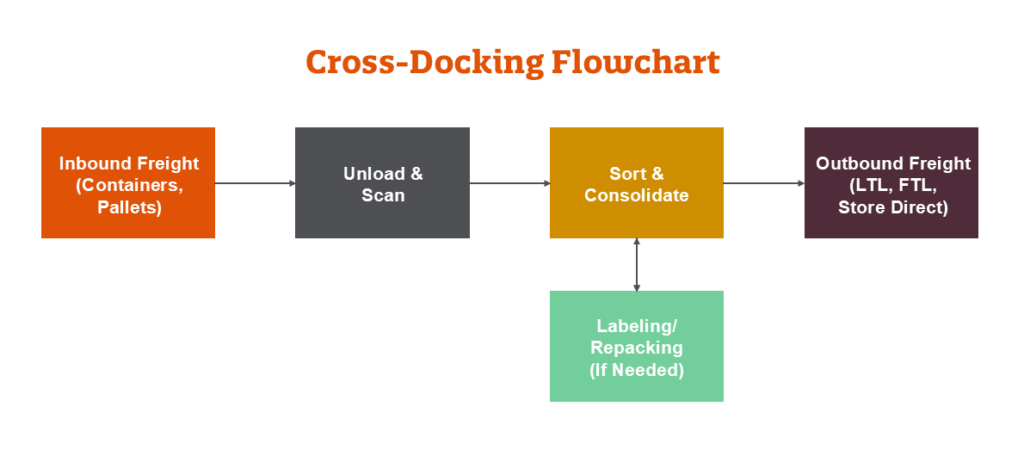

In a typical cross-docking setup:

- Inbound freight arrives at the facility

- Shipments are unloaded, sorted, scanned, and repacked as needed

- Goods are immediately loaded onto outbound trucks headed to final destinations

This strategy is commonly used at ports, rail ramps, and regional distribution centers where cargo is consolidated, deconsolidated, or redirected based on real-time demand.

This streamlined process minimizes storage time and gets products to end customers or retail shelves faster and more efficiently.

Benefits:

Cross-docking is a high-efficiency solution for businesses that need to move products quickly through the supply chain. Here’s what makes it valuable:

- Reduced storage costs – Avoid long-term warehouse fees

- Faster order fulfillment – Shorten lead times from port to customer

- Better inventory turnover – Minimize idle stock

- Lower labor costs – Less handling = less manpower

- Improved product flow – Great for time-sensitive or perishable goods

- Consolidation of shipments – Combine LTL shipments into full truckloads

- Minimized handling damage – Less time in storage reduces breakage risk

This method is especially beneficial for retailers, wholesalers, and importers managing high-volume or multi-stop distribution.

Cross-Docking vs. Warehousing: What’s the Difference?

| Feature | Cross-Docking | Traditional Warehousing |

| Storage Time | Minimal to none | Days to months |

| Handling Steps | 2–3 (unload, sort, reload) | 5+ (receive, store, pick, pack, ship) |

| Inventory Cost | Very low | Higher |

| Speed to Market | Fast | Slower |

| Ideal For | Fast-moving, consolidated, or time-sensitive goods | Long-term storage or inventory planning |